charpy impact test specimen position|charpy impact test calculations : fabrication A Charpy Impact Test involves striking a notched metal sample with a swinging pendulum. The amount of energy absorbed by the sample during fracture is then measured. This provides us with invaluable data about the material’s . O App Itaú Empresas foi desenvolvido para facilitar a gestão .

{plog:ftitle_list}

WEBO resultado da Look Loterias das 14 horas de hoje é informado nessa página logo após o sorteio, confira os sorteios das 14 hs de hoje da Look Loterias de Goiás. Participe do nosso grupo de WhatsApp e receba o resultado da Look Loterias no seu WhatsApp. Acesse o site Meu Jogo do Bicho diariamente e confira o resultado do jogo do bicho de .

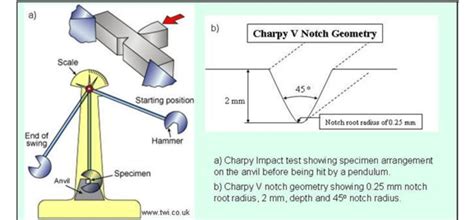

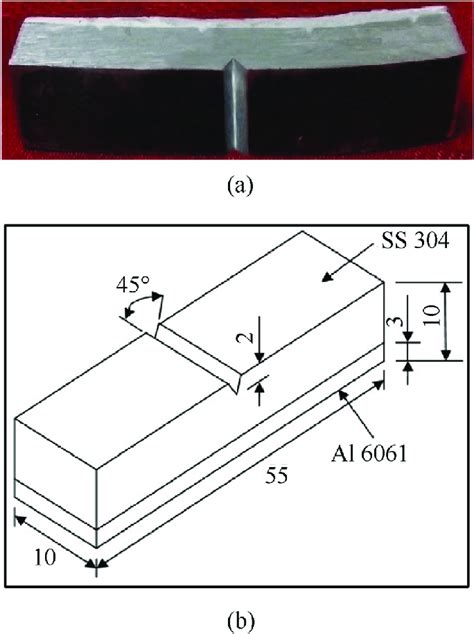

This makes Charpy testing a popular choice for assessing the toughness of metals like steel, as well as polymers, composites, and ceramics. Here’s how the process works: The test specimen, typically 55 mm long and 10 mm square with a 2 mm deep V-notch, is positioned horizontally .A Charpy Impact Test involves striking a notched metal sample with a swinging pendulum. The amount of energy absorbed by the sample during fracture is then measured. This provides us with invaluable data about the material’s .The Charpy impact test measures the energy absorbed by a standard notched specimen while breaking under an impact load [10]. This test consists of striking a suitable specimen with a .

Test setup and test procedure. In the Charpy impact test, a notched specimen is abruptly subjected to bending stress. The specimen is usually 55 mm long and has a square .

charpy v notch sample size

In a Charpy v-notch test, the specimen is placed horizontally in the pendulum impact tester and struck through the center. In an Izod impact test, the specimen is vertically gripped in the pendulum impact tester and the pendulum hammer .The ISO 148-1 standard specifies the Charpy (U-notch and V-notch) impact test on metals for determination of the impact strength. The impact strength of a material is an important characteristic for applications in pipeline construction . The Charpy impact test, sometimes called a V-notch test, is a comparative-style test used to define a material’s impact strength by determining how much energy is required to fracture a pre-prepared and standardized .In this study, we have exam-ined the influence of some of these machine/specimen variables on the results of instrumented Charpy tests, namely in terms of char-acteristic forces at general .

Charpy Impact Test Specimen Dimensions. A Charpy test specimen, which is placed horizontally into the machine, is typically a 55 x 10 x 10mm (2.165" x 0.394" x 0.394") bar with a notch machined into one of the faces. Experimental and numerical studies were performed to examine the effects of notch position on the failure behavior and energy absorption when the Charpy V-notch impact test is made at 1. °C.. Carbon steel plate (SA-516 Gr. 70) with thickness of 25 mm usually used for pressure vessel was welded by Shielded Metal-Arc Welding method and specimens were .

in contact with the anvils.This should be taken into account in future revisions of instrumented Charpy test standards. KEYWORDS:instrumented Charpy tests, impact machine variables, specimen position, t-test analysis Introduction Impact testing has a history extending back to the 1850s [1], when The standard size of a specimen for Charpy impact testing is 10 mm × 10 mm × 55 mm. A 2mm deep notch with an angle of 45° and a tip radius of 0.25mm is then machined into one face of the bar. . Double-check that the .

The value of energy absorbed is read directly from a dial on the machine. A typical impact testing machine is shown in Figure. 1. Figure 1. Schematic of a Typical Charpy Impact Testing Machine. In carrying out a test, the specimen is loaded into the anvil with a pair of special tongs that facilitate location of the specimen in the machine.The Izod test uses notched specimens similar to Charpy but while the Charpy impact test restricts the movement of both ends of the specimen, the Izod test only restricts one of the ends [42 .

Variables and Specimen Position Journal of Testing and Evaluation, (2009) Splett JD, McCowan CN, Iyer H and Wang C Computing Uncertainty for Charpy Impact Machine Test Results NIST-SP 960-18 (2008) Siewert TA Evaluation Specimens for Izod Impact Machines (SRM 2115): Report of Analysis NIST SP 260-164 (2007)The ASTM E23 standard describes notched bar impact testing of metals according to Charpy and Izod.For the test, a notched metal specimen is broken in half using a pendulum hammer. The ASTM E23 standard describes the requirements for specimens, for the performance of the test, for result reports and for testing machines, i.e., pendulum impact testers at ambient . 5.3 For this test method, the energy lost by the pendulum during the breakage of the specimen is the sum of the energies required to initiate fracture of the specimen; to propagate the fracture across the specimen; to throw the free ends of the broken specimen (toss energy); to bend the specimen; to produce vibration in the pendulum arm; to produce .

Switching gears, enter the Charpy impact test. This time, the specimen lies horizontal, chilling until a pendulum swings down to meet it. Think of it as the material’s rite of passage, testing its mettle (sometimes literally) against the merciless swing of the pendulum. . Izod Impact Test Charpy Impact Test; Position of Specimen: Vertically .

In the charpy impact test we use a test specimen which have a notch at one side of it. Figure 4 — Specimen Deformation of the material is confined to a small volume and stress in concentrated .Mechanical testing of welds. Philippa Moore, Geoff Booth, in The Welding Engineer s Guide to Fracture and Fatigue, 2015. 9.5 Charpy testing. The Charpy test measures the energy absorbed when a notched bar of material is struck with a fixed-weight pendulum swung from a given height. The absorbed energy (in joules) is also referred to as the impact toughness of the material.The reversed notch impact resistance technique is obtained by reversing the specimen in the position of a notched specimen in the vice. Here, the notch is subjected to compressive load rather than tensile stress during . 3 . . Charpy) impact test. All the test variables that have a high effect on the results, such as notch sensitivity, toss

The Charpy impact test is a widely known test famous for its accuracy in measuring metallic and plastic materials. SB Russell and George Charpy introduced this in the 20th century to measure the strength of the material. . Specimen Position . The material position has a significant influence on power transmission and fracture. For instance . Experimental and numerical studies were performed to examine the effects of notch position on the failure behavior and energy absorption when the Charpy V-notch impact test is made at 1 °C. Carbon steel plate (SA-516 Gr. 70) with thickness of 25 mm usually used for pressure vessel was welded by Shielded Metal-Arc Welding method and specimens were . Cutting the specimen is the second step in preparing U- and V-notched specimens for Charpy and Izod impact testing. The material is precisely cut into standardized dimensions during this process. Standard .An impact test consists of a striker hitting the test specimen to transfer a large force in a short time.You can use a drop tower or a pendulum tester to achieve such large forces.. A striker is dropped vertically from a height for a drop tower test and uses gravity to achieve the necessary impact energy. Similarly, in a pendulum test, the striker is fixed to an arm that swings like a .

The reversed notch impact resistance technique is obtained by reversing the specimen in the position of a notched specimen in the vice. Here, the notch is subjected to compressive load rather than tensile stress during . 3 . . Charpy) impact test. All the test variables that have a high effect on the results, such as notch sensitivity, toss

Charpy impact test pendulums are used to determine the amount of energy a test specimen absorbs during an impact (see ASTM Standard E23). . The pendulum is released from rest from an initial position of 8 = 39". The friction at pin O is negligible. 3648 in 15.25 in Test specimen

Procedure for Charpy Impact Test Specimen Preparation: Prepare a sample with dimensions of 55 mm x 10 mm x 10 mm, featuring a 2 mm notch at the center.. Test Specimen: Elevate the simple pendulum to its initial position and verify the correct adjustment of the testing machine.; Begin by calibrating the Charpy machine -rotate the dial gauge to the maximum .When testing at sub-zero temperatures the length of time taken to remove the specimen from the cooling bath, position it on the anvil and test it is most important. EN875 requires this to be done within five seconds otherwise the test piece temperature will rise making the test invalid - referring back to the impact energy vs temperature curve .Question: In Charpy impact test on plain carbon steel specimen, the following information are given: drop pendulum head weight= 22.25 kg and the drop pendulum arm = 1.34 m. If the weight is left to drop from horizontal position and the angle of rise was 65° calculate: Height of rise of the pendulum in meters

charpy impact test usual values

charpy impact test value for mild steel

Experimental and numerical studies were performed to examine the effects of notch position on the failure behavior and energy absorption when the Charpy V-notch impact test is made at 1°C.Here’s how the process works: The test specimen, typically 55 mm long and 10 mm square with a 2 mm deep V-notch, is positioned horizontally in the Charpy impact testing machine. The Charpy impact test specimen notch faces away from the pendulum, which swings down from a set height to strike the sample.

Charpy Impact Test Specimen Dimensions. A Charpy test specimen, which is placed horizontally into the machine, is typically a 55 x 10 x 10mm (2.165" x 0.394" x 0.394") bar with a notch machined into one of the faces. . Charpy vs Izod Impact Testing Comparison including materials tested, types of notches, position, striking point, dimensions .

Impact Resistance While various methods are available to test for impact strength, the Charpy method of determining impact resistance of notched specimens of plastics (ASTM D6110-10) will be used for this experiment. The impact frame will record the net energy lost by the hammer through impacting and breaking the sample.The reversed notch impact resistance technique is obtained by reversing the specimen in the position of a notched specimen in the vice. Here, the notch is subjected to compressive load rather than tensile stress during . 3 . . Charpy) impact test. All the test variables that have a high effect on the results, such as notch sensitivity, toss

What does the Charpy Impact Test Measure? . Test procedure of Charpy Test a. Specimen Preparation. The size of the sample should be 55mm x 10mmx 10mm and should have a depth of 2mm at notch at the center. a. Lift the pendulum to its starting position. Then you have to check whether the test machine has been adjusted correctly.

charpy impact test sample dimensions

charpy impact test sample

12 de fev. de 2024 · Assinar o Cartão dr.consulta com Odontologia. 2 – Cartão dr.consulta. Assinantes da modalidade do Cartão dr.consulta têm: consultas .

charpy impact test specimen position|charpy impact test calculations